As summer becomes a distant memory and the weather begins to cool, many of us have been privy to an unusual phenomenon… rain! With all the wet stuff about, and some governments altering their water restrictions, we do tend to forget about water conservation and rain water harvesting… but, let me assure you, this is THE time to think about it, not just in the warmer months! In fact, autumn and winter are excellent times to seriously consider installing rainwater tanks. If you have a rainwater tank in place now, think of all the H2O you’ll have ready to go come spring … it’s kind of like a ‘layby lifeline’ for your patch!

But with the huge range of tanks out there, heading out to buy a tank can be incredibly daunting. Luckily, SGA have come to the rescue, and have put together a ‘Sustainable Shoppers Guide’ to help you make the right rainwater decision for your place. So here is a swag of information on a number of commonly used, currently available rainwater tanks and their features, be they good, bad and ugly. Bear in mind that new products are released all the time, so, if the tank you are interested in ain’t on the list, just let us know.

Oh, and remember, with all tanks, it is recommended that you get a licensed plumber to install your tanks… it’s the only way to claim any Government rebates on the purchase price of your water holding wonder!

Buyers Guide to Tanks

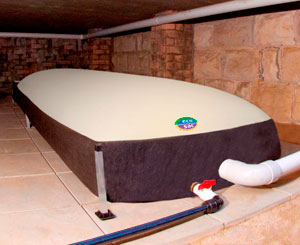

Bladder Tanks

Size/Capacity Range: 300L – 20,000L

What’s it made of? Flexible re-inforced PVC (Polyvinyl chloride) geomembrane

What’s the deal? Essentially, bladder tanks are like large, water filled wine casks. These inflatable tanks are designed to be located on top of the ground, under the floors or decks of houses, and are essentially long and thin, perfect for sitting between stumps and foundations. Many of these types of tanks are enclosed in a steel or metal frame (a good thing!), and storage capacity can be increased by installing a number of these tanks in sequence (space permitting of course).

Why we like it: They are fairly cost effective, and are more easily transported from one location to another. Bladder tanks are also a great option for people who have difficulties with access for larger, rigid tanks (bladders can be rolled up and carried through the house!). They slot away nicely ‘out of sight’ under the house, which has the added bonus of making it easier to direct downpipe water to them.

Why we don’t: Look, they are pretty tough, but they are definitely not unbreakable (or untearable), and you run the risk of voiding the warranty on a few brands of these if they are exposed to direct sunlight too long. All of them need an under house clearance of 750mm as a bare minimum, and, whatever you do, make sure that the tank is NOT blocking access to utilities (like S bends and underfloor piping), otherwise you’ll need to empty the tank to fix the problem! Oh, and for some reason, kids love to bounce on these… it’s kind of like a water filled jumping castle, so some serious kid-control is required with these!

Environmental footprint and overall sustainability: Like all tanks, it’s important to have a look at the warranty period. Many bladder tanks have fairly limited warranty lengths (about 3 yrs), which isn’t great, and means there is the potential for a great deal of PVC to end up in landfill in a relatively short space of time. This is made more significant by the fact that PVC can take a really, really long time to degrade, and even then it just ‘granulates’ (that is, big bits become smaller bits). In fact, PVC is often regarded as a contaminant in many waste streams, and less than 1% of PVC is recycled, or able to be recycled. The manufacturing process for PVC is another issue altogether, with key ingredients involved in the manufacture of PVC being oil and chlorine… two products with really big environmental footprints. It has to be said, while these tanks are cheap, the long term cost to the planet may far outweigh the initial savings you make.

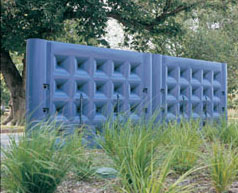

Poly (Plastic) Tanks

Size/Capacity Range: 600L – 50,000L

What’s it made of? Food Grade High Density Polyethylene (HDPE)

What’s the deal? In a nutshell, these tanks are… well… plastic tanks! Available in a massive range of colours, shapes and sizes, these tanks are essentially the plastic equivalent to the traditional Aussie corrugated tank. There are a load of companies manufacturing these tanks around the place, both in Australia and overseas, so be sure to ask where your tank was made, and what the warranty period is.

Why we like it: The flexibility in colour and size of these poly tanks is astonishing, and there is one available to suit just about every property. Don’t think you can come around to a round tank? Gone are the days of a big round tank taking up valuable space in the yard, poly tanks are now available as flat, ‘wall’ type tanks, designed to run along property boundaries, or along the side of the house, shed or garage. Carefully read installation instructions BEFORE placing one of these tanks, it’s not as easy as you think! The price of some of these tanks is pretty decent as well, although round tanks will always be cheaper than a wall type tank in the same capacity.

Why we don’t: While a great number of these poly tanks can be really cost effective, if the price seems TOO cheap, it probably is. Some unscrupulous operators are flogging inferior foreign tanks, manufactured to a different (much lower) food grade level than Aussie made tanks. Inferior plastic moulding + two tonnes of water = potential disaster! Read warranties carefully with plastic tanks, and, for your peace of mind, as well as the well being of our economy, buy an Aussie made poly tank with a nice long warranty!

Unlike bladder tanks, poly tanks need a base specially prepared before they are installed. Generally, a crushed rock and sand base is recommended for the round poly tanks, while the wall style tanks can normally sit on a flat, stable concrete or tiled base. Freestanding wall tanks often need to be braced to something to prevent them tipping over when full, so check the strength of the bracing structure (eg: the fence or shed) before attaching. The only thing worse that a tank tipping over is one tipping over and taking the shed or fence with it! Oh, and for folks in bushfire areas, an added issue is that plastic tanks do not perform well in the heat of a fire event.

Environmental footprint and overall sustainability: Well, let’s be honest here, HDPE tanks have a pretty negative environmental impact, due to their high embodied energy and the greenhouse gas emissions from the manufacturing process. Non-renewable fossil fuels are used in the manufacture of plastics (including HDPE), which also gives them a bit of a thumbs down. That said, their embodied water (the amount of water used to make them) is pretty low, especially in comparison to some other types of tanks. Can these tanks be recycled at the end of their useful life? Well the jury is still out at the moment, mainly due to the possibility that long exposure to sunlight has the potential to render these tanks un-recyclable. SGA will keep you posted on this as more info and credible research becomes available.

Steel Tanks

Size/Capacity Range: 300L – 20,000L

What’s it made of? Corrugated Steel (often lined with a polymer)

What’s the deal? These are the quintessential Aussie tank, the corro number that many of us grew up with at Grandad’s farm. They have had a serious facelift in the last few years, and are now available in a range of colours, sizes and even shapes (smaller oblong steel tanks are now available). Although there size range can be somewhat limited, they are a good looking tank, and the range of colours allows them to fit quite nicely into most domestic settings.

Why we like it: In short, these tanks look great! Instead of being hidden away behind the back of the shed, steel tanks can make a great (and useful) feature in gardens. Due to their smaller size, they are easier to manoeuvre, and loads of them come with their own stand, negating any need for preparation of a special base (as long as you place them on a level surface). If you have an awkward space or size requirement, shop around for a local manufacturer who may be able to custom make one of these babies for you!

Why we don’t: Like all things steel, these tanks can corrode over time. Smaller sizing means that, in order to be useful, you may need to install a couple of them at once to be a true water wizard. And be warned, they can be fairly expensive when compared to other tank options.

Environmental footprint and overall sustainability: Steel tanks have the lowest environmental impact of any type of modern tank, due to the low embodied energy, greenhouse gas emissions, embodied water and nitrous oxide emissions during manufacture. To be truly sustainable, choose a locally manufactured steel tank, and really cut down on transport related emissions. The planet will thank you for it!!

Concrete Tanks

Size/Capacity Range: 3,700L – 500,000L

What’s it made of? Concrete (with internal steel re-inforcement)

What’s the deal? They’re big, they’re heavy, they’re (generally) built onsite and they can have a massive capacity… concrete water tanks may not be everyone’s cup of tea, but if you are after big and tough, these guys will do the job.

Why we like it: Then biggest advantage to concrete tanks is generally their larger capacity. Essentially, concrete tanks can be hand built (or pre cast) to just about any size, from about 3,700L to 500,000L… that’s a massive amount of water. Concrete tanks can be installed either underground or above ground (and can be painted to make them look less like concrete). They are wind, vermin, sun, fire and rust proof, and the concrete keeps the water cool, clean and algae free. Often, concrete tanks can be repaired if they are damaged.

Why we don’t: Well, admittedly they are pretty ugly, and, even when installed underground, the large access area and tank roof is still quite visible. Being concrete, they are porous and can occasionally crack, allowing tree roots to penetrate and things to go pear shaped! They have a pretty limited warranty period all things considered (about 15 to 20 years), and, if they are to be used for drinking water, they may need to be flushed out several times to get rid of the ‘taste’ of concrete.

Environmental footprint and overall sustainability: Concrete tanks are generally considered to be a bit of an environmental nightmare, based on a number of lifecycle assessments conducted by respected universities and organisations. For one, concrete tanks are manufactured with both concrete and steel, meaning their inputs are pretty high. In fact, a 5000L concrete tank has about 160kg of steel re-inforcement (and weighs about 2 600kg all up). This means that, of all the commonly available tanks, concrete tanks have the highest embodied water, embodied energy and greenhouse gas emissions. There is often a large environmental impact associated with the transportation of pre-cast concrete tanks, due to their weight and the fact that they cannot be stacked in transit. On the flipside of this, there is the potential to recycle elements of the tank at the end of its useful life, particularly the steel framing.

Related Articles:

Thriving in the Heat: Managing Plant Heat Stress

As the mercury rises, your garden confronts the challenge of heat stress. Understanding how various plants respond to heat and employing appropriate…

Water Smart Gardening 101 Video

Sustainable Gardening 101 Video Series PART 4: Water Smart Gardening As the climate changes we need to take extra care to design water smart gardens.…